The Use of Thermal Insulation Nails

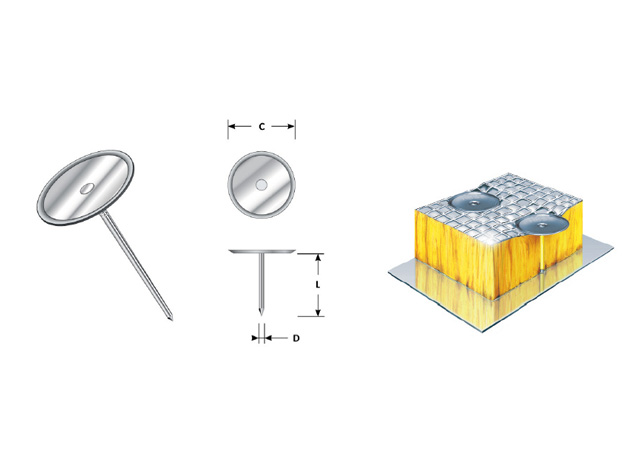

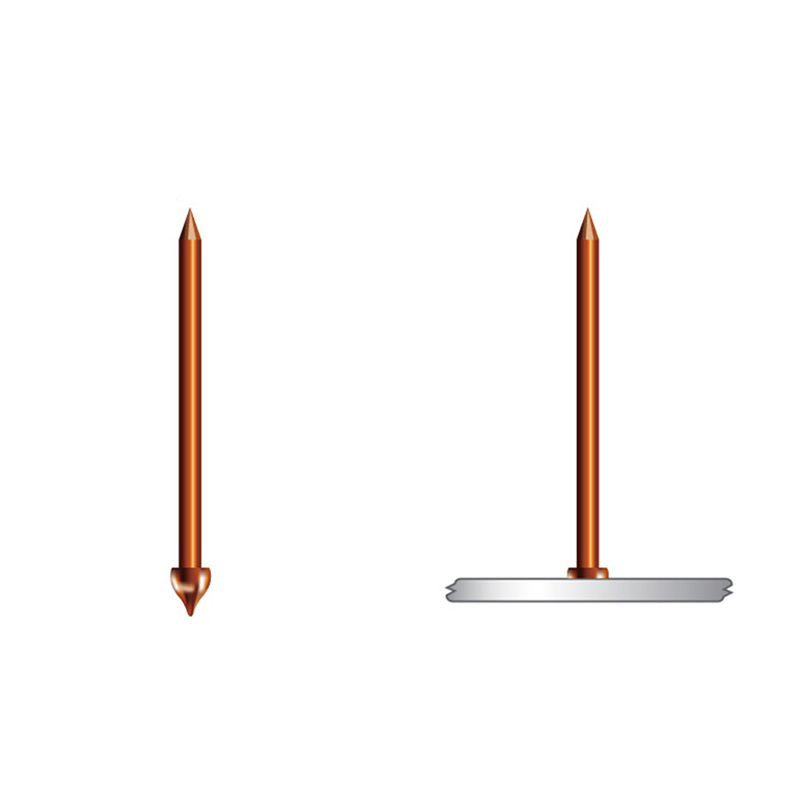

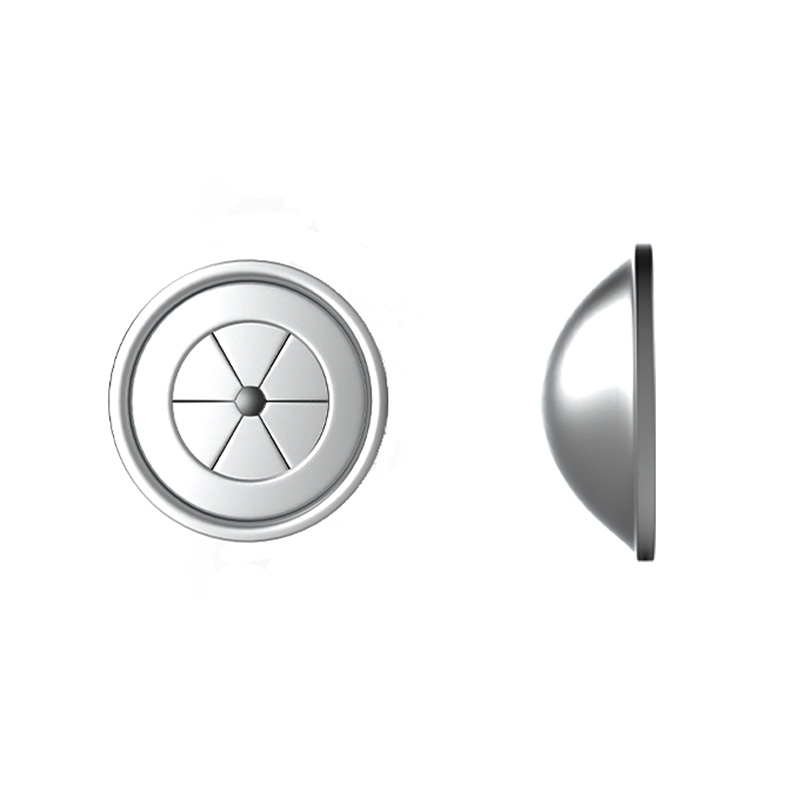

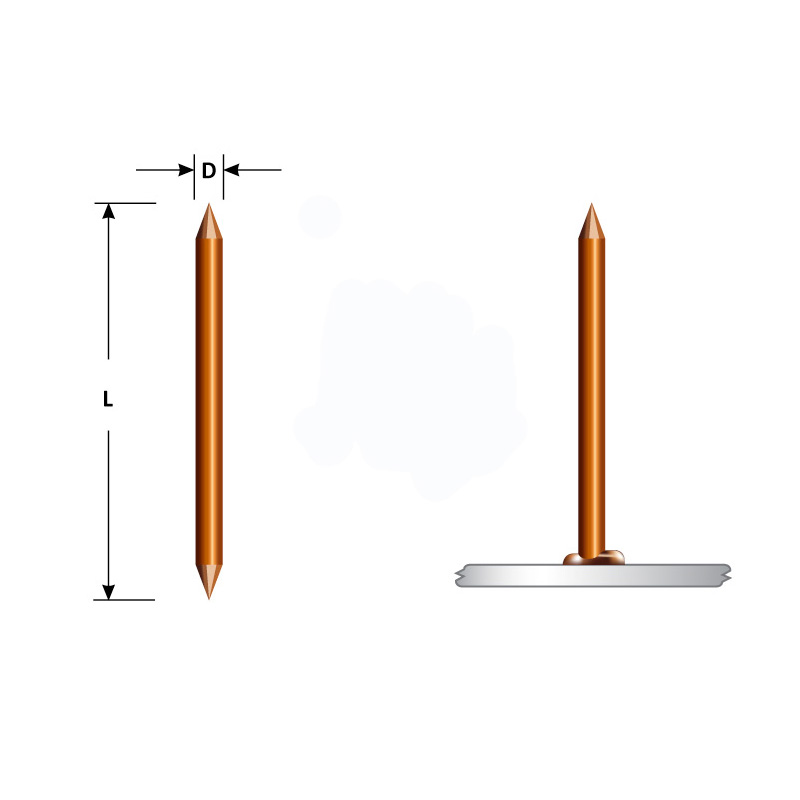

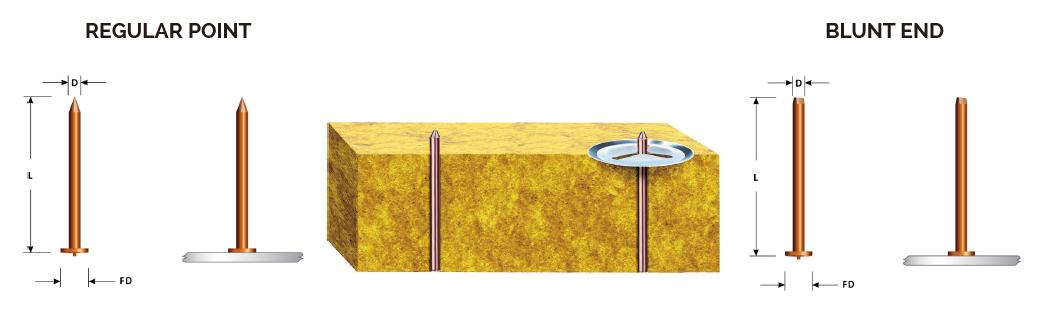

Material composition of thermal insulation nails: thermal insulation nails are composed of two parts: nails and locking pieces. The nails are made of low carbon steel or stainless steel, and then galvanized or copper-plated on the surface, and the locking pieces are made of galvanized sheet or stainless steel. The copper-plated sheet is stamped and formed.

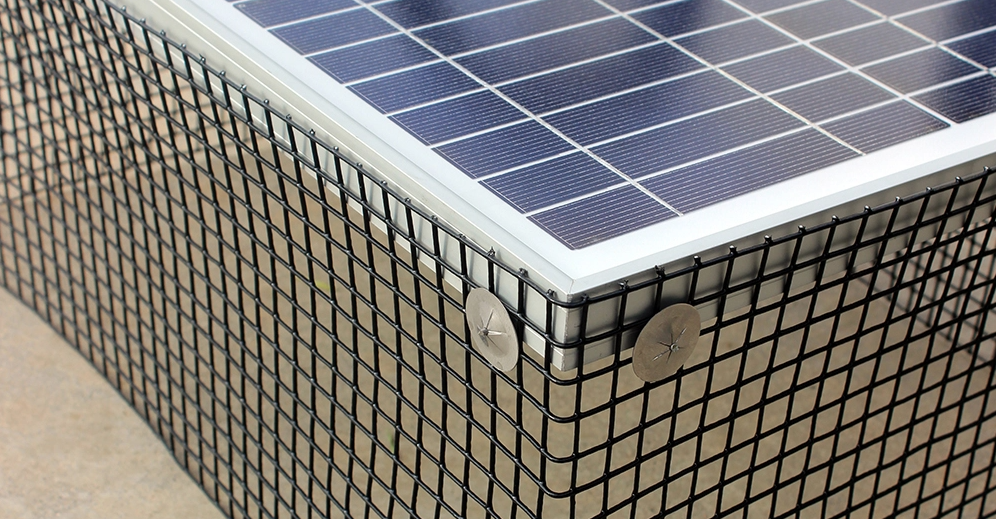

Uses: Thermal insulation nails are mainly used for thermal insulation welding of ship pipelines, thermal insulation welding of air conditioning and ventilation pipelines, thermal insulation welding of offshore oil platforms, etc. Advantages: high-quality material selection, stable quality, firm welding and high precision. The company strictly controls the properties of materials, which not only ensures good welding performance, but also meets the requirements of strength and the process requirements of cold heading.

Our factory can manufacture various special shapes and special materials according to the customer's own specifications and requirements. And through the experiment and quality assurance system, the welding performance and reliability of the product are guaranteed.

How to use: 1. Use a welding nail gun to directly weld on the equipment when installing the insulation layer on the surface of the equipment. The solder joints are very small, and the effect on the surface temperature of the equipment can be ignored.

Our factory has recently customized a batch of thermal insulation bumpers for a shipyard in Tianjin, China. The models are 3.5×85, 3.5×135, 3.5×185. The shipyard has tested them to meet international standards, and customers are very satisfied.