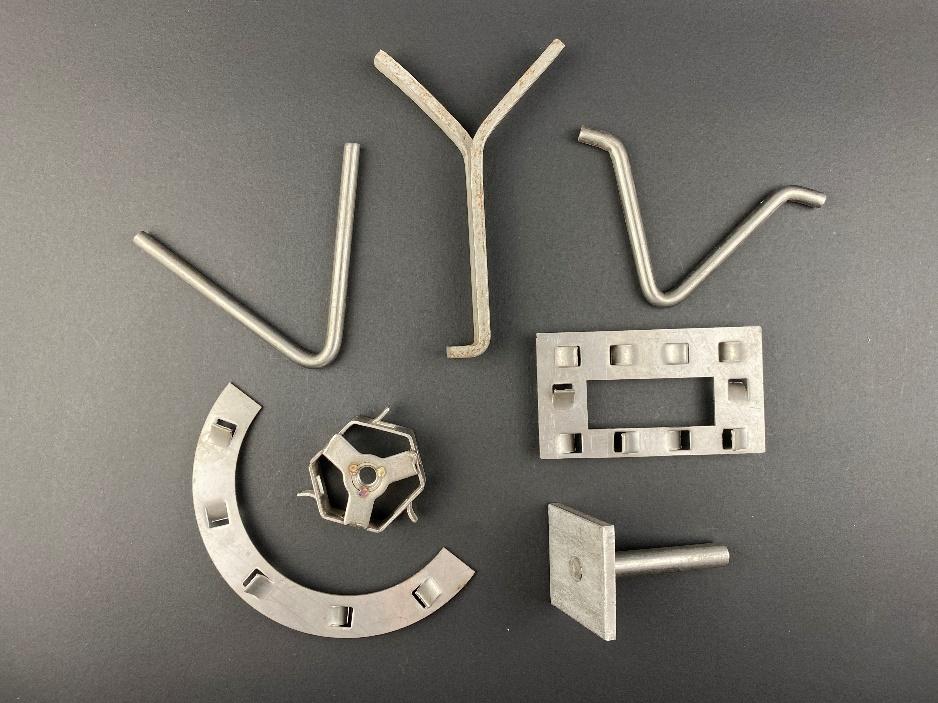

Material Selection and Classification of Stainless Steel Furnace Body Insulation Nails

In order to increase its high temperature resistance and corrosion resistance, thermal insulation nails for furnace body lining are often made of stainless steel plates or wires. Stainless steel is divided into three types according to types:

| Material number | DIN EN | Max. applicationtemperature (air) | Tensilestrength (Rm) | Tensilestrength (Rm) |

| 321 | 1Cr18Ni9Ti | 450-500℃ | 500-730 | 200 |

| 316Ti | Cr18Ni12Mo2T | 450-500℃ | 500-730 | 210 |

| 309 | 1Cr23Ni13 | 950-1000℃ | 500-730 | 230 |

1. Austenitic stainless steel: including iron-chromium-manganese, iron-chromium-manganese-nickel alloys, austenitic stainless steel is the most commonly used type, which belongs to the 200 and 300 series in the old AISI system. It is usually not magnetic. Cold working allows it to harden significantly with excellent formability and weldability. Compared with carbon steel, the thermal conductivity is low and the thermal expansion coefficient is large. The main grades are S30400 (304), containing Cr18%~20%, Ni8%~10.5%, and the rest is iron. Mainly refers to 18-8 stainless steel, these two figures represent the approximate content of chromium and nickel. It is mainly used in all kinds of equipment, including containers, pipes, construction, public facilities, decoration, and many consumer goods used in the production and processing industries of industrial products, such as sinks, water tanks, basins for cleaning, kitchen utensils, pots and flatware table utensils etc. When the workpiece needs to be welded, the commonly used low carbon steel grade S30403 (304L)

2. Ferritic stainless steel: including iron-chromium alloys. It has the corrosion resistance of stainless steel and is sometimes difficult to weld when made. Magnetic. It can be hardened slightly when cold worked. The varieties are: S40900 (409), containing Cr10.5%~11.7%, S43000 (430), containing Cr16%~18%, the basic element is iron. Consumer goods made from ferritic stainless steel are less expensive, such as automotive exhaust systems, trim and flatware.

3. Martensitic stainless steel: mainly iron-chromium alloys. It has higher carbon content and other hardeners than ferrite. It is magnetic. Strong, strong and less ductile than austenite. Heat-treatable strengthening. Not easy to weld. Typical steel grades are S41000 (410), containing Cr11.5~13.5%, carbon content of 0.15%, and other elements being iron. Its main use is to make corrosion-resistant bearings, scissors, valves and compressor parts. Austenitic stainless steel is often used as a material for making furnace insulation nails because of its high temperature corrosion resistance and excellent forming and welding functions. However, the contact with the punching machine during the stamping and forming process of the stainless steel anchor will produce

A certain weak magnetic phenomenon, that is, the slight transformation of the microstructure of austenitic stainless steel to martensitic stainless steel, in order to completely eliminate the magnetic properties of 304 steel caused by the above reasons, high temperature solution treatment can be used to restore the stable austenite structure, thereby Remove magnetism. But it will not affect the construction of the project. The stainless steel furnace body anchor in our factory guarantees the material, and the spectrometer can be used to measure the composition comparison of its stainless steel trace elements.