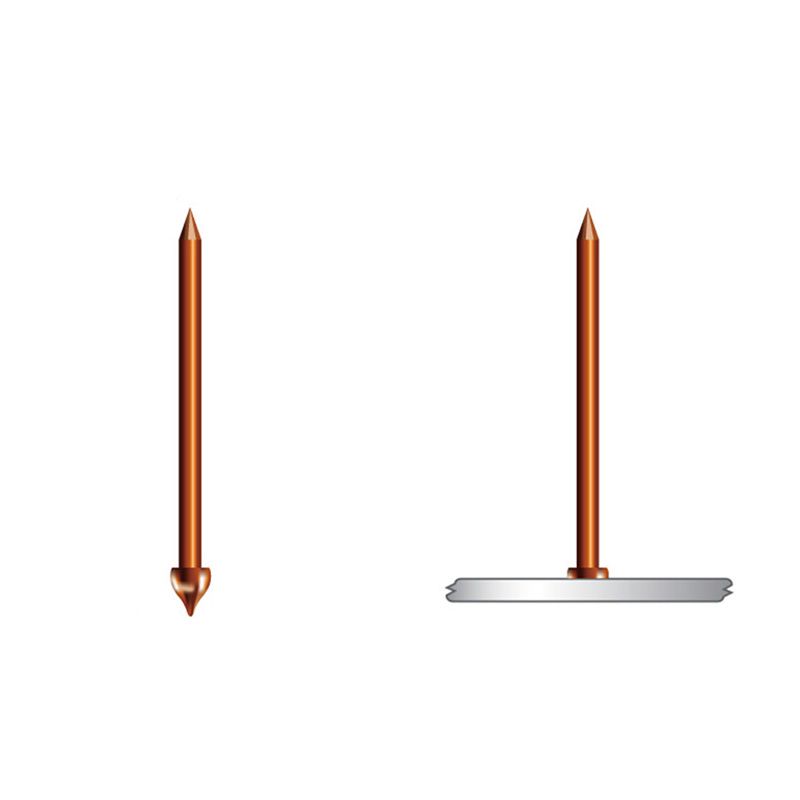

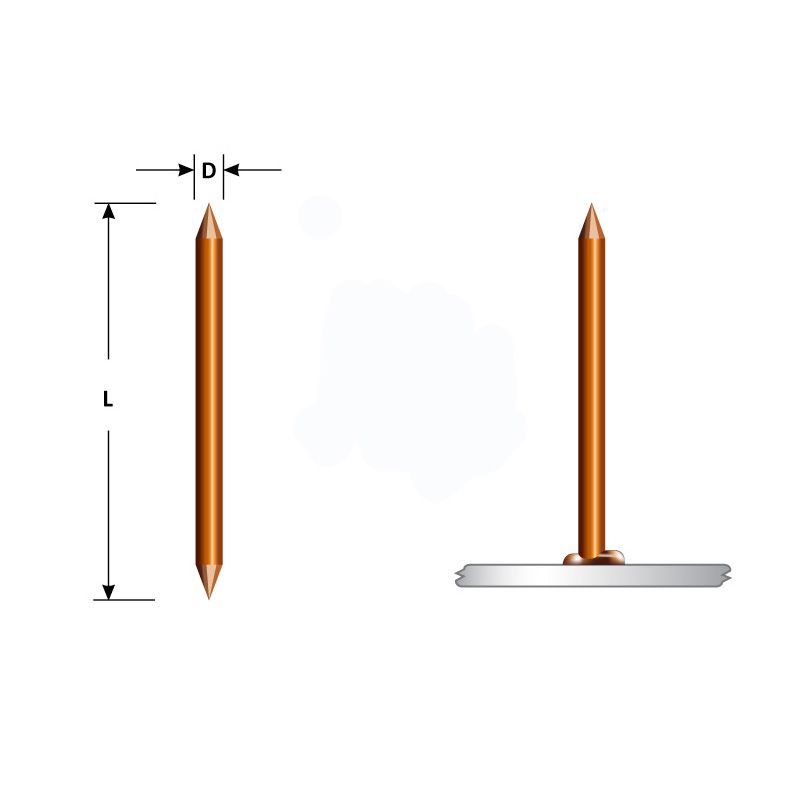

Welding Studs Customized for Korean Customers

Recently, we received a special request from a Korean customer and customized a batch of special thermal insulation studs for the construction of oil pipelines in Africa. The diameter of this batch of welding studs is 3.5mm, and the welding point is designed with a five-pointed star, which is easier to weld to the pipe. , The surface is copper-plated, smooth and clean. After a month of hard work, under the premise of ensuring quality, 600,000 sets of insulating nails were delivered to customers. It has been well received by customers.

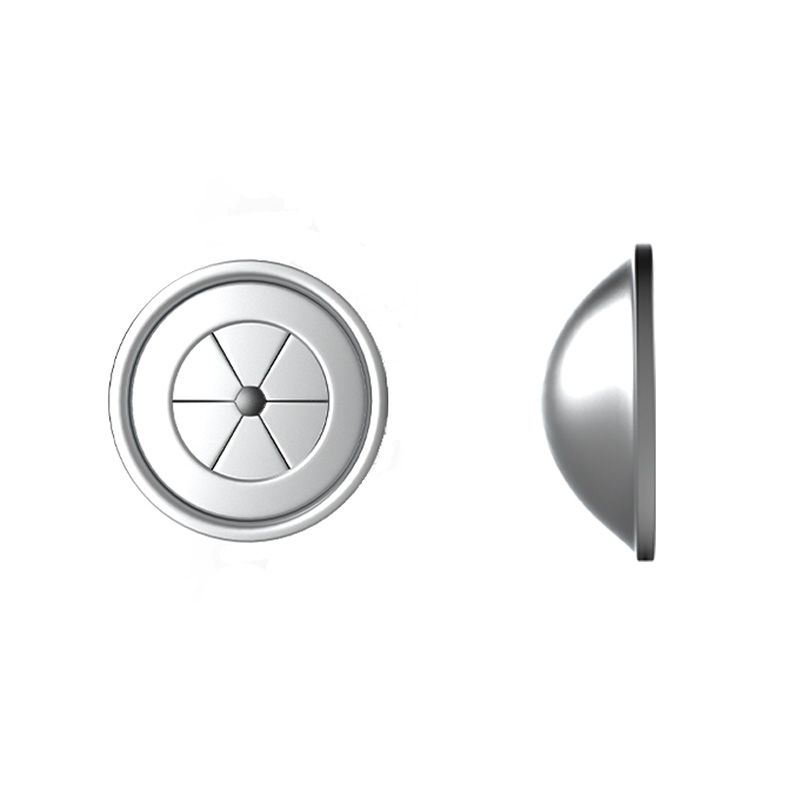

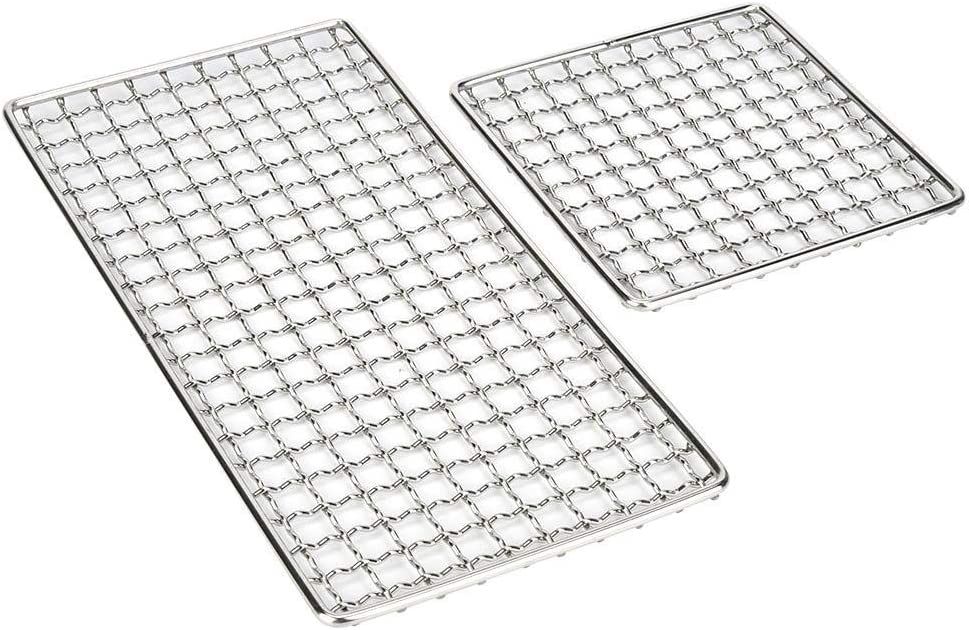

Welded insulation nails

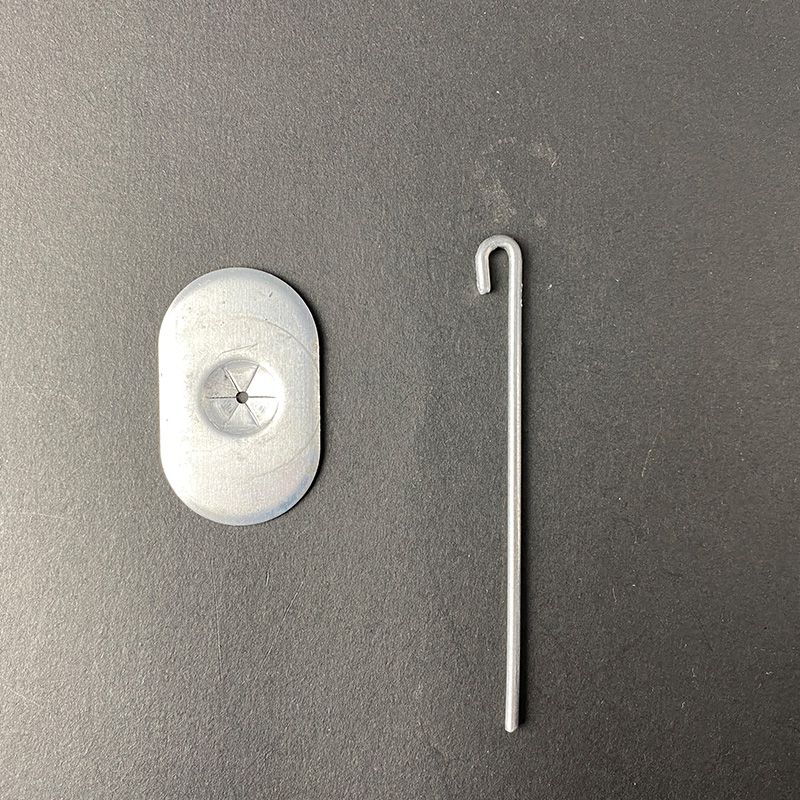

The material is made of galvanized sheet and carbon steel wire by machining, which is an air conditioner or pipeline engineering thermal insulation material to fix a new product. Its advantages: simple operation, convenient construction, no pollution.

The traditional method is to first use adhesive to stick the insulation nails to the surface of the air duct, and then fix the insulation board with insulation nails after drying. When using pressure-sensitive tape to bond, this process not only has high environmental requirements, but also It is easy to waste insulation materials. After a long time, the insulation nails will fall off due to the aging of the adhesive, resulting in poor insulation and waste of a lot of cold or heat. Insulation nail welding insulation technology is currently the leading technology in the world, mainly in the following aspects:

(1) Through the control of the thermal insulation nail welding machine, the moment the thermal insulation nail penetrates the thermal insulation layer and contacts the pipeline, it is firmly welded on the surface of the air duct. It will not fall off before the normal life of the duct,

(2) The speed of the thermal insulation nail welding machine is much higher than the bonding speed, and does not require any solidification time, which is conducive to shortening the construction period and bringing benefits to the customer's investment as soon as possible.

(3) The welding of insulation nails will not produce any toxic gas and other pollution caused by the adhesive, and will not leave any waste on the construction site.

(4) Because the process is firm and reliable, and the construction is fast, the project cost is reduced.

(5) Insulation coils can be used in the construction of this process, which saves insulation materials and reduces project capital investment.